1. The bed is designed as box type with rigid structures for ensure heavy duty cutting & excellent heavy loading capability.

2. All the main components are made of FC-30 high quality casting and annealing heat treatment for deformation-free.

3. Three point support on the spindle are inspected by dynamic balancing, the spindle gear is a module & wide that is very suitable heavy cutting and being with 3 steps hydraulic auto. speed shifting. Especially that can be full power output even as the spindle speed at low gear, large cutting force, and spindle headstock is designed with oil cooler for reduce the temperature of oil ensure accuracy.

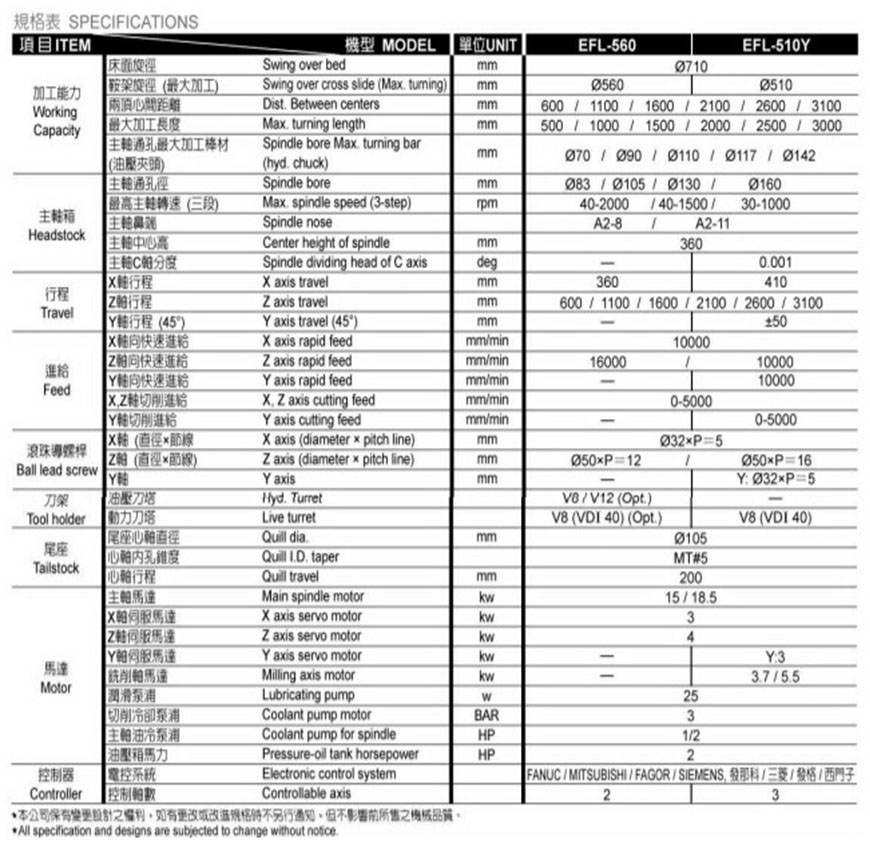

4. Differentiate spindle bore into φ83mm, φ105mm, φ103mm, φ160mm, which can be machining big & small workpieces, and it can be fitted with optional rear chuck (Opt.) for long workpiece machining ensure safety.

5. Four guide way on the machine & X/Y/Z axis are square design, Z axis is correctly at the center of bed for uniform loading, ensuring increased accuracy.

6. Model of EFL-560 can be fitted H4 four way electric turret, V8 or V12 turret and driven tool system that enable the machine to fully develop its machining performance.

Model of EFL-510Y can be fitted VDI 40 drive turret with Y-axis (travel ±50mm), which design provides cutting & milling the best choice.

7. Adopted central lubricating system which can be lubricated slide way & ball screw the forced lubricating ensure accuracy.

8. The visual window of sliding safety door be adopted the reinforced glass at inner layer and out layer for polycarbonate can be protected the failure workpieces hi-safety.

Comment